Electroplating Companies Reveal: Copper’s Secret Power

Behind the scenes, electroplating companies are doing much more than adding gloss. Plating is a critical process that strengthens components, enhances conductivity, and extends product life. Among the many techniques available, the copper electroplating solution is one of the most versatile and widely used. It forms the foundation for other finishes, improves durability, and ensures reliability in countless everyday products.

What Copper Electroplating Achieves

At first glance, copper plating might appear ordinary compared to gold or silver finishes. Yet copper consistently surprises manufacturers with its effectiveness. One striking result is its superior conductivity.

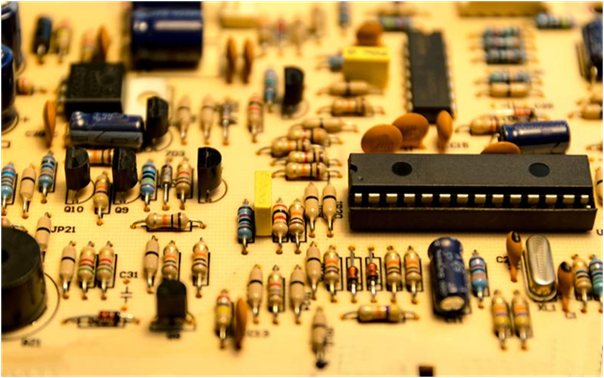

Electroplating companies use copper as a base layer in electronics because it ensures efficient energy transfer, making it indispensable for connectors and circuit boards.

Another surprising outcome is its role in creating a smooth, uniform surface for further plating. For example, when a decorative or protective finish such as nickel or chrome is required, copper electroplating provides the ideal underlayer. Without it, final coatings may appear uneven or fail to adhere properly.

What surprises many clients is how copper plating combines affordability with functionality. It delivers industrial-strength results at a fraction of the cost of precious metals, proving that effectiveness isn’t always about price.

More Than Meets the Eye

While copper electroplating’s visible results are impressive, some of its most valuable features remain hidden. One benefit is improved corrosion resistance. By acting as a buffer between the base metal and external conditions, copper helps prevent oxidation and wear, particularly in harsh environments.

Another hidden strength is its machinability. Copper-coated surfaces are easier to polish, solder, or shape, which saves time during production. Electroplating companies also highlight copper’s role in heat management. Its excellent thermal conductivity makes it ideal for components exposed to high temperatures, such as automotive parts and semiconductors. These show that copper electroplating is a strategic choice that enables industries to produce safer, longer-lasting, and more efficient products.

Insights from the Plating Industry

Professionals in electroplating companies often stress that success lies in preparation and precision. According to experts, the biggest mistake clients make is underestimating the importance of cleaning before plating. Even microscopic contaminants can lead to uneven coatings or weak adhesion.

Experts also recommend choosing the right copper electroplating solution for the intended purpose. For example, acid copper baths are excellent for decorative finishes. Alkaline solutions may be better for functional layers in electronics.

Another piece of advice is to work closely with providers to set clear specifications. Thickness, hardness, and intended application all influence how copper plating should be applied.

Finally, industry specialists emphasise ongoing quality control. Regular monitoring of bath chemistry, temperature, and current density ensures consistent results. This attention to detail separates reliable electroplating companies from those that deliver surface shine.

What Clients Should Look For

For businesses or individuals searching for plating services, it helps to have an essential checklist. First, ensure the provider has experience with copper electroplating solutions across different industries. Versatility is a sign that they can adapt to your unique needs.

Second, ask about compliance with international standards. Medical, automotive, and aerospace industries in particular demand strict quality assurance, and reputable companies will have certifications to demonstrate this.

Third, evaluate their facilities. A reliable electroplating company should maintain modern, well-monitored equipment to guarantee consistency.

Finally, consider aftercare support. Does the company provide guidance on maintenance, or do they hand over the finished product? A partner who offers insights beyond the plating process often delivers greater long-term value. This checklist ensures you’re selecting a provider and building a partnership that protects your investment.

Conclusion

Copper electroplating might not dazzle like gold or silver, but its real strength lies in reliability, affordability, and versatility. This solution proves indispensable across industries. Electroplating companies know that copper isn’t just a foundation, but it’s the silent powerhouse enabling products to perform, endure, and excel. For businesses searching for smarter solutions, copper plating is less about appearances and more about ensuring long-term success.

Looking for dependable plating services? Explore Epson Plating today and discover how a copper electroplating solution can power performance across industries.