Silencing the Noise: How EMI & EMC Filters Are Powering the Electronics Revolution

In our hyper-connected world, electronic devices are everywhere—from smartphones and laptops to medical machinery and industrial control systems. But what often goes unnoticed is the invisible interference that can disrupt their seamless operation. The unsung heroes—EMI and EMC filters ensuring everything runs smoothly, without glitch or interruption.

The Unseen Challenge: Electromagnetic Interference

Electromagnetic interference (EMI) can be considered an uninvited guest in electronic circuits, causing unexpected disruptions. It’s caused when one device unintentionally affects another through electromagnetic signals. In daily situations, this could mean a buzzing sound in your speakers when your phone is too close or a dropped connection in your Wi-Fi router.

This interference doesn’t just cause inconvenience—it can lead to significant failures, especially in critical sectors like healthcare, aerospace, and automotive industries. This highlights the increasing importance of EMI EMC filters.

Understanding EMI and EMC Filters

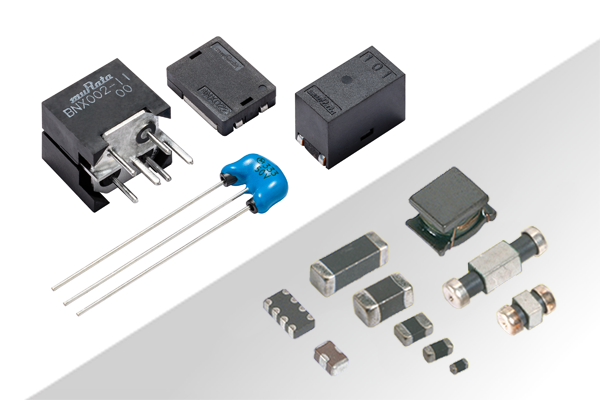

So, what exactly are these filters? EMI filters are wonderful electronic components designed to help reduce unwanted interference on power or signal lines, ensuring smoother and clearer operation. In simpler terms, they block the noise before it reaches or leaves a device. Meanwhile, EMC filters are designed to ensure Electromagnetic Compatibility (EMC), making sure that devices can function properly without interfering with one another.

The demand for these filters is rising rapidly, pushing the limits of innovation among EMI filter manufacturers in India. These filters have virtually limitless applications, ranging from compact consumer electronics to large industrial systems.

Why Indian Manufacturing is Stepping Up

India has been emerging as a hub for high-quality electronic components. EMI filter suppliers in India are carving out a reputation for delivering precision-engineered and performance-driven products. This shift is driven by growing local demand, export potential, and a renewed focus on building reliable, efficient electronics domestically.

Electronic components manufacturers role is no longer just about mass production. It’s about designing innovative solutions that integrate seamlessly into modern electronic ecosystems. Whether it’s a simple appliance or a complex piece of industrial equipment, EMI filters are at the heart of it.

Real-World Applications That Make an Impact

Let’s break down where these filters make a difference:

- Healthcare Equipment: A single disruption can be fatal in life-saving devices like MRI machines or patient monitors. EMC compliance ensures their consistent performance.

- Automobiles: Modern vehicles are tech-driven, loaded with sensors and computing units. Electromagnetic Interference (EMI) filters play a vital role in preserving signal integrity and preventing operational malfunctions.

- Telecommunications: With 5G rolling out and internet devices increasing, signal clarity and system reliability are critical. Filters act as gatekeepers for uninterrupted communication.

- Consumer Electronics: Everything from your smart fridge to your gaming console needs EMI protection to prevent short circuits and ensure user safety.

- Defense Systems: These high-precision systems cannot afford interference. Custom-engineered EMI and EMC filters are vital here.

Features That Matter in a Great Filter

Not all filters are created equal. Here are a few features that define an excellent product:

- Low leakage current to ensure safety in sensitive environments

- High attenuation levels for effective noise suppression

- Small dimensions enable effortless integration in space-limited applications

- Wide voltage range support for versatile use

- Thermal endurance for harsh operational conditions

These aspects are top priorities for every leading EMI filter manufacturer India has to offer, with innovation driving new product designs regularly.

Selecting the Appropriate Filter: Key Considerations

When you’re in the market for the right EMC filter, consider the following:

- Application Type: A medical-grade filter is not the same as one for industrial machinery.

- Input/Output Voltage: Ensure the filter can handle your system’s range.

- Regulatory Compliance: Look for certifications related to safety and performance standards.

- Reliability: Filters should have a long service life with minimal maintenance.

Collaboration with an experienced EMI filter supplier in India can help customize the solution to fit your system perfectly.

The Future Is Filtered

As electronic systems become more complex and intertwined, the margin for error shrinks. Smart cities, IoT networks, electric vehicles, and next-gen medical tech are just a few arenas where EMI and EMC compliance are non-negotiable.

For brass manufacturers, plastic suppliers, or CNC component makers, the “silent operation” concept might sound poetic—but for EMI filter developers, it’s literal. Filters will continue to affect the dependable operation of the hidden mechanisms of the world.

While they may not be the most visible components, EMI and EMC filters are the backbone of modern electronic stability. Thanks to innovations led by EMI filter manufacturers in India, industries can now access smarter, more resilient, and efficient filter solutions. Whether setting up a new communication line, designing a medical device, or engineering a high-speed train system, the right filter makes all the difference. Silence, after all, is golden—especially when it powers a world that never stops running.