The Rising Demand for Hybrid Vehicle Production

In recent years, the global automotive industry has been shifting its focus toward sustainability and energy efficiency. Hybrid vehicles, which combine the benefits of traditional fuel engines and electric motors, are becoming increasingly popular among environmentally conscious consumers. This growing interest has led to a major rise in hybrid vehicle production across many countries, including Vietnam, where the manufacturing sector continues to evolve rapidly. Behind this transformation lies the vital role of advanced manufacturing technologies, especially those found in a CNC machine shop, which helps carmakers meet the precision demands of hybrid systems.

What Drives the Popularity of Hybrid Vehicles

Consumers today are more aware of the environmental impact of their choices. Rising fuel costs, stricter emission regulations, and growing concerns about climate change have pushed car manufacturers to innovate. Hybrid vehicles offer a middle ground between conventional gasoline cars and fully electric models, providing both improved fuel efficiency and reduced carbon emissions.

In Vietnam and other parts of Asia, governments are encouraging green mobility through tax incentives and infrastructure support. As a result, more car manufacturers are investing in hybrid models to meet both local and export demands. However, producing these vehicles is not as simple as it seems. Each component, from the engine to the battery housing, requires exceptional precision and consistency to function flawlessly together. This is where automotive machining comes into play, ensuring that every part meets the tight tolerances necessary for hybrid technology.

The Role of Advanced Manufacturing in Hybrid Vehicle Production

Manufacturing hybrid vehicles involves an intricate combination of mechanical and electrical components. Each part must work seamlessly within a limited space while maintaining high performance and reliability. Traditional manufacturing methods often fall short of these requirements. That’s why companies increasingly rely on high-tech machining processes that can deliver accuracy at scale.

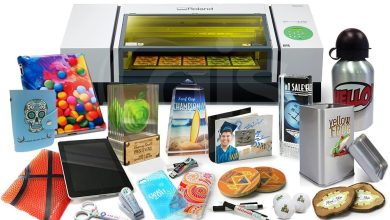

A modern CNC machine shop is essential in this process. Using computer-controlled equipment, engineers can design and produce parts with incredible precision. From engine blocks to transmission components, CNC machining ensures that hybrid vehicle systems are built to perfection. This technology also allows for quick adjustments in design, helping manufacturers keep up with the rapid evolution of hybrid technology.

How Automotive Machining Supports Innovation

The backbone of hybrid vehicle production is precision engineering. Automotive machining plays a crucial role in this area by allowing manufacturers to produce complex parts with minimal errors. For example, the integration of electric motors into combustion engines requires highly detailed components that traditional machining might not achieve efficiently.

With advanced equipment, such as multi-axis CNC machines, manufacturers can produce intricate parts that support high-performance hybrid drivetrains. Automotive machining also contributes to lightweighting efforts, which are vital for improving fuel efficiency. By using materials like aluminum or composite alloys and machining them precisely, carmakers can reduce vehicle weight without compromising strength or safety.

Vietnam’s Growing Role in the Hybrid Vehicle Market

Vietnam’s manufacturing sector is entering an exciting new phase, with several domestic and international companies investing in automotive technology. As global automakers look for cost-effective production hubs, Vietnam offers a promising environment due to its skilled workforce and expanding industrial infrastructure.

Local suppliers and CNC machine shop owners are adapting quickly to meet international standards. They are investing in better equipment, training, and automation to serve the hybrid vehicle industry. This not only boosts Vietnam’s position in the global supply chain but also creates opportunities for high-value manufacturing jobs that contribute to the country’s economic growth.

Challenges and the Road Ahead

Despite the progress, challenges remain. Hybrid technology requires precision at every level, and even small deviations can impact performance. Manufacturers must maintain strict quality control while keeping production costs competitive. Additionally, as the industry transitions toward more electric-focused solutions, suppliers will need to stay flexible and embrace continuous innovation.

This evolution will continue to depend heavily on technologies such as CNC machining and precision manufacturing systems. The more advanced these processes become, the better equipped manufacturers will be to meet future automotive demands.

Conclusion

The rise of hybrid vehicle production reflects a larger shift toward a more sustainable and efficient automotive industry. From concept to assembly line, every stage depends on precision engineering and advanced manufacturing. The capabilities offered by a CNC machine shop and the expertise behind automotive machining are driving this transformation forward, helping manufacturers build cleaner and smarter vehicles for the modern world.

Contact Disk Precision Group to learn more about how advanced manufacturing can enhance your automotive projects.